Weight grader for melons, Chinese okras and mini-watermelons.

ALL-STAINLESS-STEEL MODULAR DESIGN ? HIGH-RATE, OPEN-ENDED SYSTEM !

SETOP’s ERGONE combines ergonomics and the respect of health-safety standards. It is a grader for melons, Chinese okras and mini-watermelons, for all types of productions.

With a grading capacity of 12,000 fruits per hour and per line, it will handle all production volumes, from the smallest to the largest.

MELON GRADER in 4 arguments

- Suitable for melons, Chinese okras and mini-watermelons.

- All-stainless structure

- Silent. Minimum maintenance.

- Modular. Achieves rates of 5 to 30 t/h.

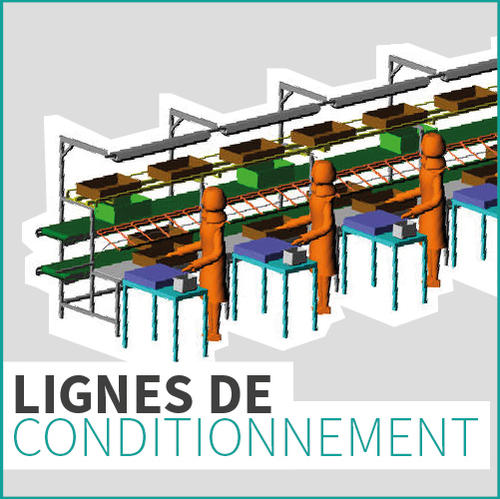

Medium production workshop.

Large production workshop.

ERGONE can grade fruits up to 3 kg (mini-watermelons).

The weighing systems is made of stainless steel, the weighing cups sliding over extremely durable polyurethane shoes that are self-cleaning and insensitive to dust.

Of modular design, it allows adapting to and meeting optimally all production volumes.

ERGONE is the most silent of all graders thanks to its original weighing and conveying system on a conveying belt. ERGONE requires very little maintenance and is very economical.

The workstations on ERGONE can be over trays or buffer conveyors. The packing trays are large-capacity, 1.20 m wide by 1.30 m deep.

The machine features a high-gloss white protective coating that does not get dirty, making for ease of maintenance.

The conveying system is simple and robust, with a white or green non-toxic PVC-coated belt featuring holes spaced out so as to allow the line to be 100% filled including with the largest of melons.

At the exits deflectors spread out the melons with great softness onto the buffer conveyors or into the trays.

Of compact built and with a reduced number of legs, cleaning around the machine is easy, while the stainless-steel construction allows reduced and durable maintenance.

ACCESSORIES

Tray Packing Desk

Of all stainless construction, the packing desks above the trays are removable, light and unobtrusive, and designed to the make the removal of full crates easy.

The desk’s angle is very easy to set, according to the height of the operator or the grade of the melons to be packed.

It is easily removable and allows changing the workstation’s configuration or cleaning the tray.

Made of thin bars, the space between the bars allows a better sight of the fruits to be packed and is suitable for all crate sizes.

Thanks to its rollers full crates can be removed with a minimum of effort. They are directed automatically towards the palletisation area.

IT, setting and production-management parameters:

Windows 10 interface.

Setting of grading thresholds.

Chutes can be configured towards different trays.

Production counters. Weighing control.

OPTIONS

Sorting belts, with optional lighting, detection of rejects, automatic feeding to grader.

Fed by a pallet-box emptyer.

Removal of rejects takes place at the packing stations.

Peripherals are available to suit all needs: feeding of empty crates, removal of full crates, etc.

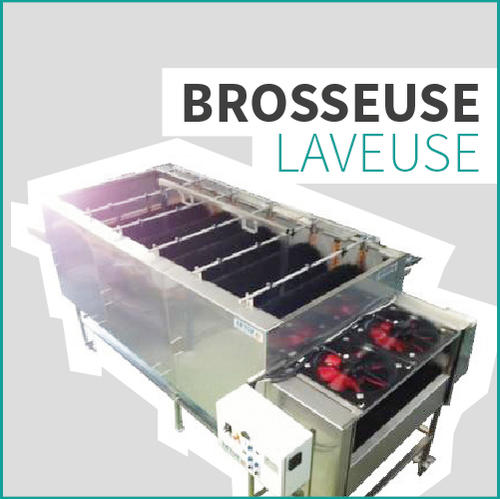

Brushing-machine, cleaner, dryer, etc.