COLIBRI is a mini-grader for the grading of all kinds of fruit.

Furnishes the fruits’ distribution in kilograms in accordance with the standard grades for batches of apples, peaches, apricots, kiwis, etc. as received.

COLIBRI in 3 arguments

- Provides an estimation of production batches prior to sorting.

- Helps meet demand in terms of market segments.

- Allows anticipating the grade distribution of produced fruit

COLIBRI is a mini-grader that non-destructively grades representative samples of fruits. It takes just a few minutes to establish the distribution of batches of fruits per grades and categories according to the applying standards.

The machine can be used with all kinds of fruits and is intended for production units that need to know in real time the contents of the deliveries they receive.

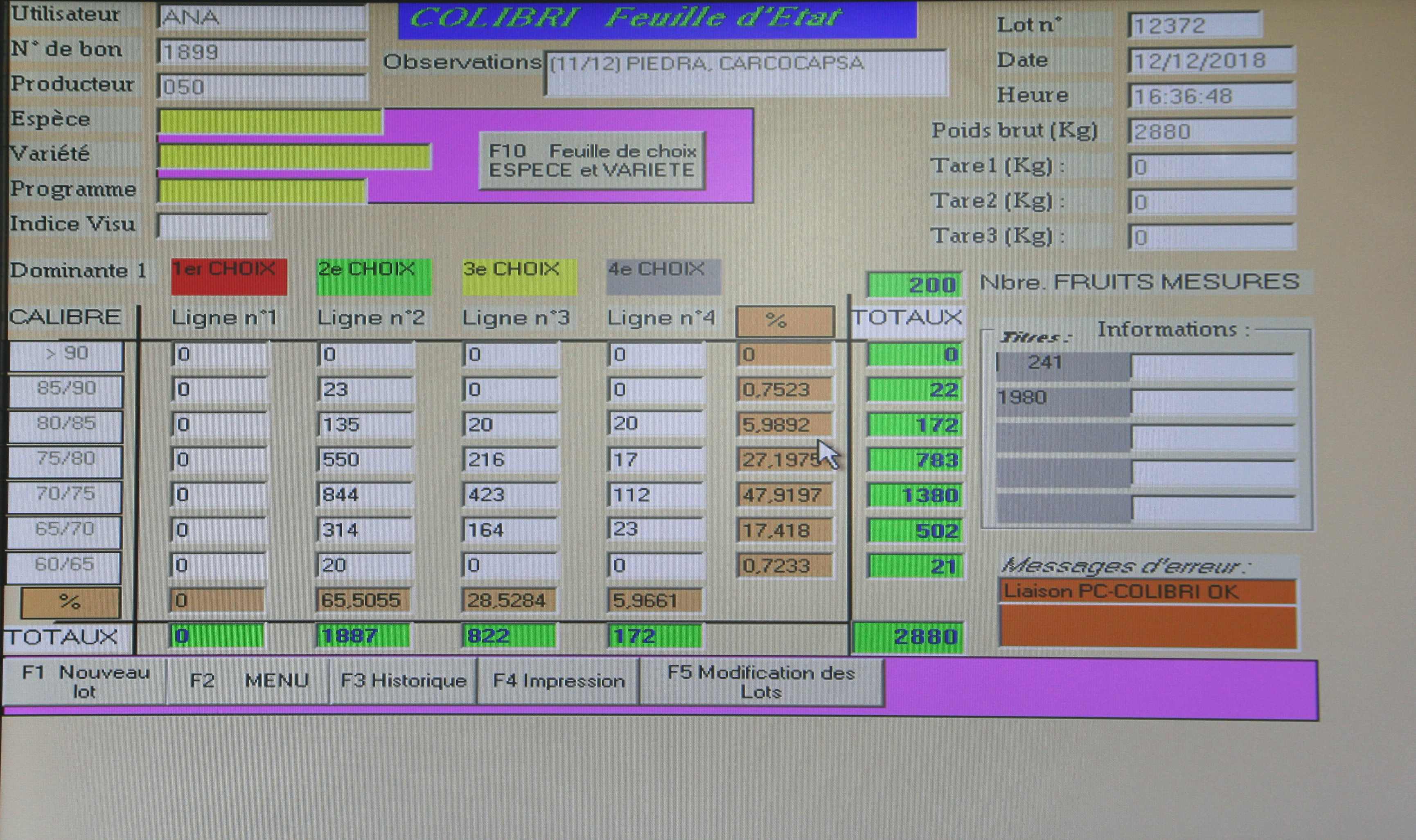

COLIBRI prints out a grading report in kilograms from the weight of the received batch. Connected to the company’s IT systems, it provides immediate and complete traceability.

COLIBRI is comprised of two parts:

- A cabinet, size 60 × 60 × 160 cm, ingress protection rating IP 55, allows installation in hostile environments (such as delivery platforms). The lower section is closed and houses the industrial electronics for the control of the machine’s grading functions. The top section houses the IT components (PC, monitor, keyboard, mouse, printer); it is the operator station and is open during operation.

- The grading section, linked to the cabinet through communication cables. It features a conveying belt provided with 4 lines of holes of special design, onto which the grading operator places the fruits according to their categories. This allows having 4 choices, but several rows can also be allocated identical choices, according to 6 pre-set combinations. The fruits are graded by an optoelectronic system by diameters according to European standards. Once graded they are fed to an exit tray, from which they can rejoin the other fruits delivered.

The computer works with an open database which stores for each species and variety the nominal average weigh of each grade. From the fruits’ average weight and grades the software computes a theoretical sample weight, giving a percentage for each grade and category.

The operator enters at the keyboard the received batch’s real weight and tares (from the warehouse’s reception scales, which are normally regularly controlled for accuracy). The software breaks down the net received weight in grades and categories from the percentages established for the sample.

The system’s precision is ensured: even if a produce features a different density relative to the average weight stored in the database, the difference applies proportionally to all grades without the percentages being changed. The final distribution thus remains unchanged.

The machine prints a grading report that shows the identification parameters and the breakdown into different categories and grades.