Automatic machine for the quality control of melons, for production grading, varietal selection or sorting by species.

Measures the weight, firmness and sugar content of melons, taking a photograph of each fruit.

TOPVII in 4 arguments

- Optimises the quality control of melons.

- Measures quickly and reliably sugar content, weight, diameter, firmness and takes a photograph of each fruit.

- Collects the data in an Access database.

- Allows the large-scale monitoring of quality for entire productions or in varietal research programmes.

SETOP TOPVII

TOPVII - Its advantages

Production

SORTING

VARIETAL

SELECTION

Proven technology

Modular

ALREADY USED

by large seed and melon producers

TOP VII automatically measures the sugar content (in Brix degrees), grade (diameter, weight) and firmness of melons. It can also take and store a picture of the fruits and identify them with a bar code. It can achieve sorting rates of 800 to 1,500 melons according the functions implemented.

TOPVII grades all types of melons (Cantaloupe, Charentais, Honeydew, Sprite, Piel de Sapo, etc.).

TOP VII works with an Access database and features data export in the Excel format.

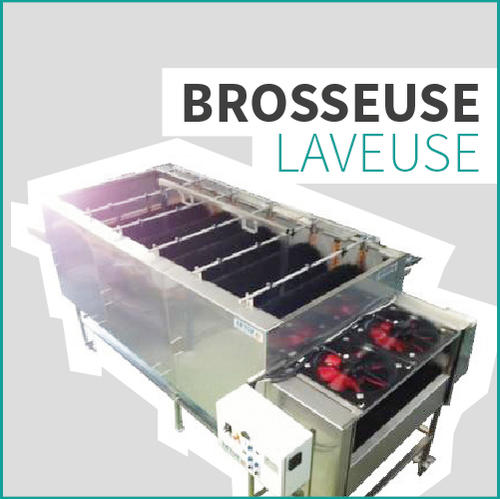

Designed to operate in the harshest of conditions, TOPVII is built in stainless steel. This makes it dust- and moisture-resistant and simple and easy to maintain. It is easy to operate thanks to its touchscreen.

TOPVII is comprised of a sampling plate, a conveyor, a computer and a printer. The conveyor is fitted with barcode reader, scales, firmness measurement and a camera for photographing each fruit.

The analysis the fruits’ sugar content is carried out according to the “TOP” process, which allows fast and precise measurements without impairing the fruits’ conservation potential.

Each melon placed on the conveyor is automatically identified by the barcode reader, weighed, graded, photographed, its firmness measured. Then a micro-sample of its flesh is taken and analysed by a refractometer to establish its sugar content. The micro-sample is then replaced inside the fruit.

The whole process takes just under a second (0,95 s). After each sampling all the parts of the sampling mechanism are automatically cleaned and disinfected. The whole process is controlled by a computer, which stores the data for each fruit in an Access database.

The software also allows the manual entry of the data for the tested batches: slip number, producer name, total weight, tare, variety, etc.

The data can be exported in the Excel format to any storage supports and through any IT networks.

TOPVII is available in different configurations to best suit clients’ needs, in particular as a self-contained platform that can be transported easily for use on different production sites in succession.

TOPVII is available for sale or for rent.